PNG is the world’s second-largest balsa producer after Ecuador. It’s a very competitive global market that includes several Central American countries as minor players. Midgley says that ACIAR’s research program cast a light on an otherwise rather secretive industry.

‘The beauty of our ACIAR project was that we could release all this know-how as public information. Up until then, the global balsa market was very hushed because it was so competitive. We’ve have had substantial interest in our published reports, and the market was very happy to see them made public.’

With increased transparency of markets and improved knowledge of balsa production, Midgley says that smallholders have been able to grow high-quality balsa more efficiently. The research also explained the significance of the balsa value chain to smallholders, offering them the opportunity to assess land-use options and provide increased income streams to their families and communities.

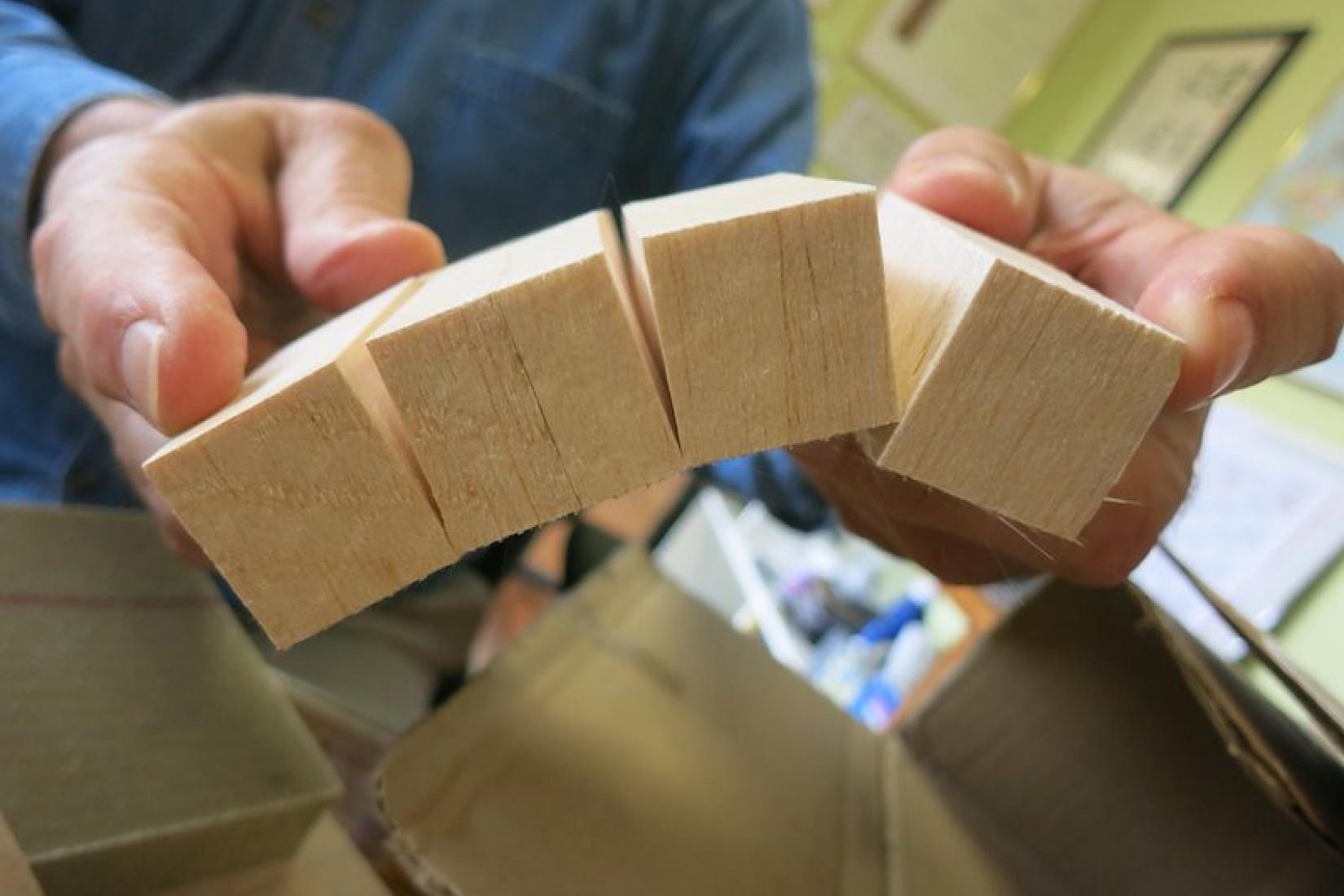

Midgley is clearly passionate about balsa. His eyes light up as he talks about its many sophisticated applications and prospects for the future. ‘Most recently, balsa has found application in renewable energies, and specifically the interior of wind turbine blades. It’s also used for boat construction, such as in the hulls of racing boats and decking on yachts. And about 30% of the balsa produced globally has military applications, such as aircraft cargo pallets.’

Servicing these products and markets are all prime examples of ACIAR-funded research having tangible outcomes for both Australian businesses and government defence.

ACIAR PROJECT: Improving the Papua New Guinea balsa value chain to enhance smallholder livelihoods (FST/2009/016)